Address: No. 69, Jintong Road, Binhai Industrial Park, Xiangshan, Zhejiang

TEL:0086-574-65802978

Mobile:0086-13626819899

E-mail:nbklbj@nbkaili.com

1. Mould use range The various tools and products used […]

1. Mould use range

The various tools and products used in our daily production and life range from the base of the machine tool and the shell of the machine body to the shell of a screw, button and various household appliances, all of which are closely related to the mold. The shape of the mold determines the shape of these products, and the processing quality and precision of the mold also determine the quality of these products. Because of the different materials, appearance, specifications and uses of various products, the molds are divided into non-plastic molds such as casting molds, forging molds, die casting molds, stamping molds, and plastic molds.

2. General definition of mold: In industrial production, various presses and special tools installed on the press are used to make metal or non-metallic materials to produce parts or products of the required shape through pressure. Such special tools are collectively called molds. .

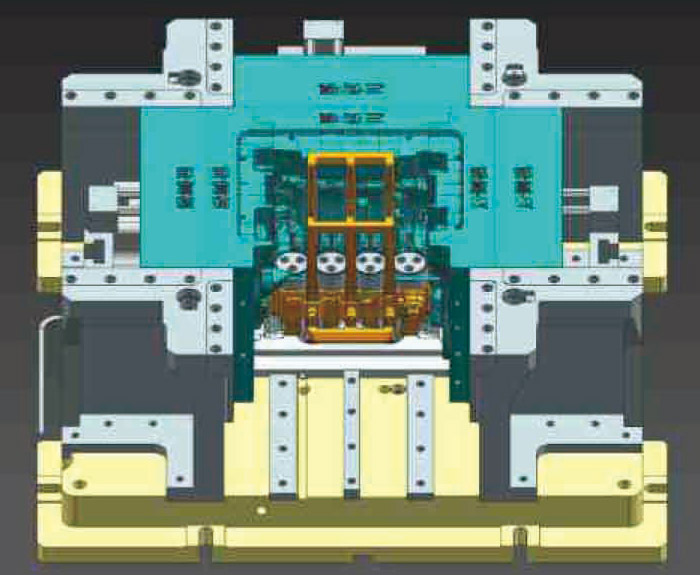

3. Description of injection molding process: The mold is a tool for producing plastic products. It consists of several groups of parts, and there is a molding cavity in this combination. During injection, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and cooled and shaped in the cavity, then the upper and lower molds are separated, and the product is ejected from the mold cavity through the ejection system to leave the mold. For the next injection, the entire injection process is cyclic.

3. Description of injection molding process: The mold is a tool for producing plastic products. It consists of several groups of parts, and there is a molding cavity in this combination. During injection, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and cooled and shaped in the cavity, then the upper and lower molds are separated, and the product is ejected from the mold cavity through the ejection system to leave the mold. For the next injection, the entire injection process is cyclic.

4. The general classification of molds can be divided into plastic molds and non-plastic molds:

(1) Non-plastic molds include: casting molds, forging molds, stamping molds, recovery molds, etc.

A. Casting mold-faucet, pig iron platform

B. Forging die-car body

C. Stamping die-computer panel

D. Die casting mold-super alloy, panic

(2) Plastic molds are divided into:

A. Injection molding mold-TV shell, keyboard buttons (the most common application)

B. Blowing mold-beverage bottle

C Li Gu Yu Shang Shang Tuan-Bakelite switch, scientific porcelain dishes

D. Transfer molding die-integrated circuit products

E. Extrusion mold-glue tube, plastic bag

F. Thermoforming mold-transparent molded packaging shell