Address: No. 69, Jintong Road, Binhai Industrial Park, Xiangshan, Zhejiang

TEL:0086-574-65802978

Mobile:0086-13626819899

E-mail:nbklbj@nbkaili.com

Gravity casting is one of the main ways to obtain the b […]

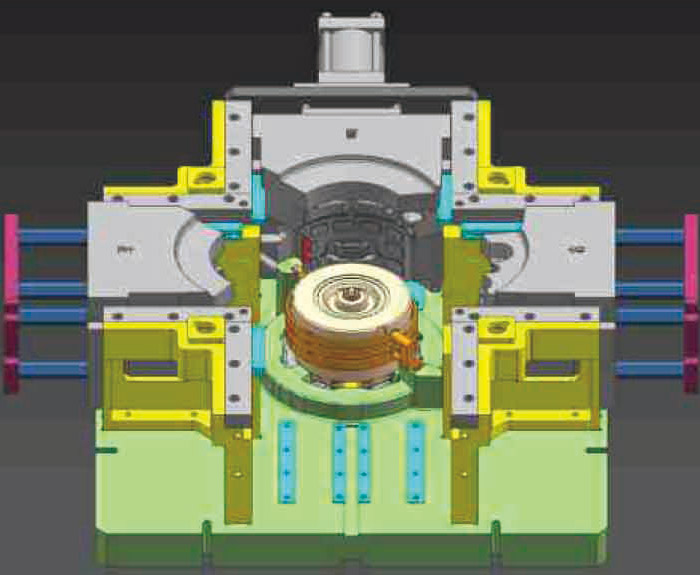

Gravity casting is one of the main ways to obtain the blanks of mechanical casting products. Although advanced equipment is an indispensable factor to ensure product quality, the role of molds in the casting process is also very important. The quality of gravity casting molds of different materials will also be different. The following will introduce the basic materials of gravity casting molds by Kuntai.

There are usually three materials for gravity casting molds, 45# steel, ductile iron and H13 steel. The gravity casting mold of 45# steel material is about 25 days from the beginning of design to the first trial mold, and the service life of the mold is about 1 to 15,000 mold times. The design of the gravity casting mold made of ductile iron is also about 25 days from the design to the initial test mode. The service life of the mold is about 1 to 15,000 molds. The price of ductile iron is cheaper than 45# steel, and it is easier to form.

The design of the H13 steel gravity casting mold takes about 35 days from the design to the initial trial mold. The service life of the mold is 80,000 molds, but the price is higher, which is more expensive than the gravity casting mold made of 45# steel and ductile iron. The mold manufacturing industry will develop towards specialized production and high-level production in the future, and Kuntai will also actively improve its technical level and ability to strive for the development of mold manufacturing.