Address: No. 69, Jintong Road, Binhai Industrial Park, Xiangshan, Zhejiang

TEL:0086-574-65802978

Mobile:0086-13626819899

E-mail:nbklbj@nbkaili.com

1. Forging forming die: Forging and casting are the mos […]

1. Forging forming die: Forging and casting are the most commonly used processing techniques for producing parts and components. Forging dies mainly include: die forging and forging dies for large presses, forging dies for screw presses, and flat forging dies , Roll forging dies, etc. At the same time, fastener cold heading dies, extrusion dies, wire drawing dies, liquid forging dies, etc. are also forging dies.

2. Stamping die: It is also called stamping die. In the cold stamping process, the stamping die processes the materials to obtain the process equipment of the parts. This type of die mainly includes punching die, bending die, drawing die, single-process die, composite die, progressive die, automobile cover die, combined die, and motor silicon steel die.

3. Plastic molding mold: Due to the wide application of plastic in life, plastic molding is also a very common processing material in the industrial field. So in order to process plastics, in the mold, there are plastic molding molds: compression molding molds, extrusion molds, injection molds, thermosetting plastic injection molds, extrusion molding molds foam molding molds, low cutter tool foam injection molding molds, and Blow molding molds are all plastic molding molds.

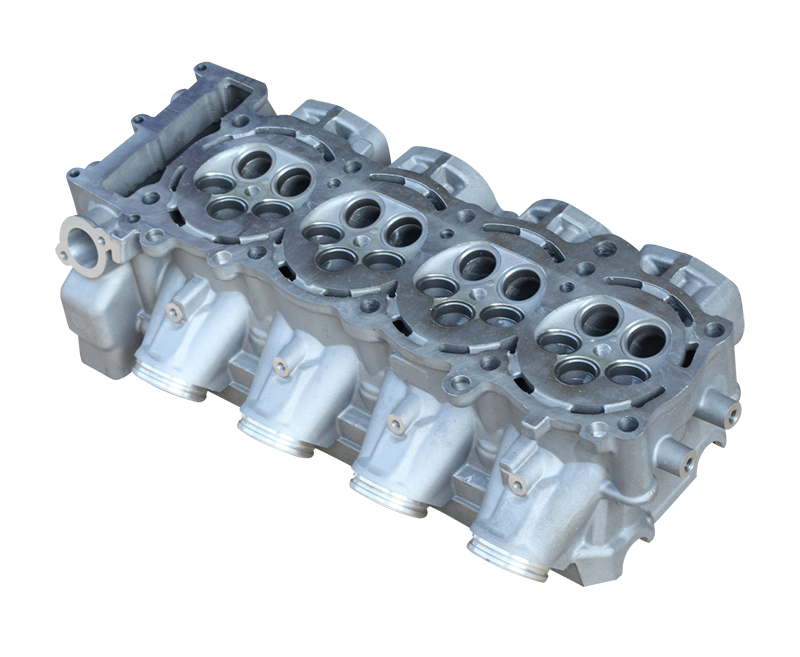

4. Metal mold for casting: This type of mold has some similarities with die-casting mold, but it is more focused on casting, the metal model used in the casting of various metal parts.

5. Die-casting molds: castings are one of the more common types of parts in production and processing. Die-casting molds mainly include die-casting molds for hot-chamber die-casting machines, horizontal cold-chamber die-casting machines, and vertical cold-chamber die-casting machines. Die-casting molds, non-ferrous metal die-casting and ferrous metal die-casting molds for full vertical die-casting machines.

6. Powder metallurgy mold forming mold: The powder metallurgy mold forming mold is relatively complex, mainly including: manual mold, motorized mold, one-way sleeve type, two-way stamper, sleeve type floating stamper, and shaping die. Among these types, there are subordinate categories. Among them, for example, manual molds also include: radial shaping molds, full shaping molds with outer step sleeves, shaping molds with spherical parts, etc.

7. Moulds for glass products: Moulds for glass products are mainly classified according to the processing form. The former is a forming bottle mould, the latter is a forming bottle mould, and a glassware mould.

8. Rubber forming mold: At this time, rubber processing molds mainly include rubber pressing mold, extrusion rubber mold and injection mold.

9. Ceramic mold: forming metal mold for various ceramics and other products.

10. Economical mold (simple mold): This is also a processing mold commonly used by some small enterprises. Because it is economical, it is very popular with everyone. This type of mold mainly includes: low melting point alloy forming mold, thin plate die, laminated die, silicone rubber die, epoxy resin die, ceramic type precision casting die, etc.